主流波纹电阻器模型之间的比较差异

I. 介绍

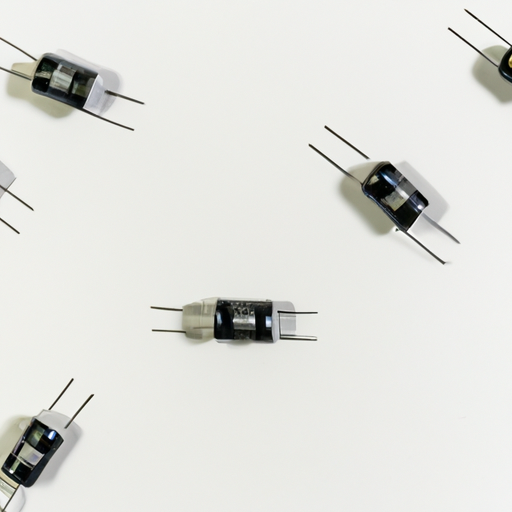

A. 波纹电阻器的定义

波纹电阻器是专门设计用于管理和散热电阻产生的热量的电气元件。它们独特的波纹结构增加了表面积,从而提高了热管理和效率。这些电阻器广泛应用于各种应用中,从功率电子学到汽车系统,精确的电阻和散热是至关重要的。

B. 波纹电阻器在电气工程中的重要性

在电气工程中,控制和管理热量的能力至关重要。过多的热量可能导致元件故障、效率降低和安全隐患。波纹电阻器在确保电气系统在安全温度范围内运行方面发挥着至关重要的作用,使其在现代电子设计中不可或缺。

C. 比较的目的

本博文旨在比较主流波纹电阻器模型,突出它们的规格、性能特征、材料组成和用户考虑因素。通过了解这些差异,工程师和设计师可以在选择适合其应用的正确电阻器时做出明智的决定。

II. 波纹电阻器模型概述

A. 主流模型描述

1. **模型A**:以其高功率评级和出色的热管理而闻名,模型A通常用于高性能应用。其设计侧重于最大化散热,同时在负载下保持稳定性。

2. **模型B**:该模型以其性价比和多功能性而闻名。它提供了平衡的性能,适用于各种应用,因此在工程师中很受欢迎。

3. **模型C**:模型C专为需要精确电阻值和最小温度漂移的专业应用而设计。其独特的结构使其在苛刻环境中表现出色。

B. 波纹电阻器的应用

1. **功率电子学**:波纹电阻器在功率电子学中至关重要,它们有助于管理变流器、逆变器和其他高功率设备中的热量。

2. **汽车行业**:在汽车应用中,这些电阻器用于制动系统、电动驱动和电池管理系统,可靠性和性能至关重要。

3. **工业设备**:波纹电阻器还用于各种工业设备,包括电机驱动器和控制系统,确保在不同负载下稳定运行。

III. 比较的关键规格

A. 电阻值

波纹电阻器的电阻值在不同模型之间可能会有显著差异。模型A通常提供更广泛的电阻值范围,适用于高功率应用,而模型B提供更标准的范围,满足一般需求。

B. 功率评级

功率评级对确定电阻器在不过热的情况下能够承受多少功率至关重要。模型A通常拥有更高的功率评级,使其成为要求严格的应用的理想选择,而模型B和模型C可能具有较低的评级,但在特定用例中表现出色。

C. 温度系数

温度系数表示电阻器的电阻随温度变化的程度。模型C以其低温度系数而闻名,在温度波动的环境中保持稳定性,而模型A和模型B可能具有较高的系数。

D. 公差水平

公差水平表示电阻器电阻值的精度。模型C通常提供更严格的公差,适用于需要高精度的应用,而模型A和模型B可能具有更宽松的公差。

E. 物理尺寸

物理尺寸可能会影响电阻器安装和集成到系统中。由于其坚固的设计,模型A通常较大,而模型B和模型C可能更紧凑,便于集成到空间受限的应用中。

IV. 性能特征

A. 热管理

1. 散热

有效的散热是波纹电阻器的特点。模型A在这方面表现出色,利用其波纹设计最大化表面积并增强冷却效果。模型B也表现良好,但可能无法与模型A的效率相匹配。

2. 工作温度范围

模型A通常在更广泛的温度范围内运行,适用于极端条件。相比之下,模型C设计用于精确性,可能具有较窄的工作范围。

B. 负载稳定性

1. 短期与长期性能

模型A在不同负载下表现出色,无论是短期还是长期,而模型B可能会随时间而有所下降。然而,模型C即使在长时间压力下也能保持稳定性。

2. 负载变化的影响

模型A和模型C更适合处理负载变化,而模型B在快速负载变化下可能会出现电阻波动。

C. 频率响应

1. 交流与直流性能

在涉及交流的应用中,由于其出色的热管理,模型A通常表现优异。模型B对交流和直流应用都很灵活,而模型C则针对直流性能进行了优化。

2. 阻抗特性

模型C通常表现出较低的阻抗特性,适用于高频应用,而模型A和模型B可能具有较高的阻抗,影响其在特定场景中的性能。

V. 材料组成

A. 波纹电阻器中常用的材料

1. **金属合金**:许多波纹电阻器利用金属合金的导电特性。模型A通常采用高质量合金以提高性能,而模型B使用更具成本效益的材料。

2. **陶瓷基板**:陶瓷基板在高温应用中很常见。模型C经常采用先进陶瓷以确保耐用性和稳定性。

B. 材料对性能的影响

1. 电导率

材料的选择直接影响电导率。模型A的高质量合金提供了优越的电导率,而模型B的材料可能导致略低的性能。

2. 耐久性

耐久性对于长期性能至关重要。模型C使用先进陶瓷增强其耐久性,使其适用于恶劣环境,而模型A和模型B可能不够坚固。

3. 成本影响

材料选择也会影响成本。模型B通常是最具成本效益的选择,而模型A和模型C可能因其先进材料和结构而价格较高。

VI. 主流模型的比较分析

A. 模型A vs. 模型B

1. 优势和劣势

模型A的优势在于其高功率评级和出色的热管理,使其成为要求严格的应用的理想选择。然而,它可能比模型B更昂贵,后者在较低成本下提供了平衡的性能。

What kind of product is a load resistor?

System

Sep 15

0

What Kind of Product is a Load Resistor? I. IntroductionIn the world of electrical engineering, load resistors play a crucial role in ensuring the stability and functionality of various electronic circuits. But what exactly is a load resistor? In simple terms, a load resistor is a component that provides a specific resistance to an electrical circuit, allowing it to function correctly under various conditions. This article will delve into the definition, types, applications, and selection criteria for load resistors, highlighting their importance in modern electronics. II. Understanding Resistors A. Basic Principles of ResistanceTo understand load resistors, we first need to grasp the basic principles of resistance. Resistance is a measure of the opposition to the flow of electric current in a circuit, and it is governed by Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R). This relationship can be expressed with the formula:\[ V = I \times R \] B. Function of Resistors in CircuitsResistors serve several essential functions in electrical circuits:1. **Current Limiting**: Resistors can limit the amount of current flowing through a circuit, protecting sensitive components from damage.2. **Voltage Division**: They can divide voltage in a circuit, allowing different components to operate at their required voltage levels.3. **Signal Conditioning**: Resistors can shape and modify signals, ensuring that they are suitable for processing by other components. III. What is a Load Resistor? A. Definition and PurposeA load resistor is a specific type of resistor used to simulate a load in a circuit. Its primary purpose is to provide a known resistance that can absorb power, allowing engineers to test and evaluate the performance of power sources, amplifiers, and other electronic devices. By creating a controlled load, engineers can analyze how a circuit behaves under different conditions. B. Differences Between Load Resistors and Other ResistorsWhile all resistors share the fundamental property of resistance, load resistors are distinct in their application. Unlike standard resistors, which may be used for current limiting or voltage division, load resistors are specifically designed to handle higher power levels and dissipate heat effectively. This makes them essential for testing and simulating real-world conditions in various applications. C. Common Applications of Load ResistorsLoad resistors are commonly used in several applications, including:- Testing power supplies and inverters- Simulating loads in automotive systems- Evaluating audio equipment performance- Calibrating industrial machinery IV. Types of Load Resistors A. Fixed Load Resistors 1. CharacteristicsFixed load resistors have a predetermined resistance value that does not change. They are typically used in applications where a constant load is required. 2. ApplicationsFixed load resistors are commonly found in power supply testing, where they provide a stable load for evaluating the performance of power sources. B. Variable Load Resistors (Rheostats and Potentiometers) 1. CharacteristicsVariable load resistors, such as rheostats and potentiometers, allow users to adjust the resistance value. This flexibility makes them suitable for applications requiring different load levels. 2. ApplicationsThese resistors are often used in audio equipment for volume control and in testing scenarios where varying load conditions are necessary. C. Electronic Load Resistors 1. Definition and FunctionalityElectronic load resistors are advanced devices that can simulate various load conditions electronically. They can adjust their resistance dynamically based on the input signal, making them ideal for testing and simulation. 2. Applications in Testing and SimulationElectronic load resistors are widely used in research and development, allowing engineers to test power supplies, batteries, and other devices under varying load conditions. V. How Load Resistors Work A. Basic Operation PrinciplesLoad resistors operate on the principle of converting electrical energy into heat. When current flows through a load resistor, it encounters resistance, which causes energy to be dissipated as heat. The amount of heat generated is proportional to the power (P) consumed, which can be calculated using the formula:\[ P = I^2 \times R \] B. Role in Circuit StabilityBy providing a known load, load resistors help stabilize circuits, ensuring that voltage and current levels remain within acceptable ranges. This stability is crucial for the reliable operation of electronic devices. C. Heat Dissipation and Thermal ManagementEffective heat dissipation is vital for load resistors, as excessive heat can lead to component failure. Many load resistors are designed with heat sinks or other thermal management features to ensure they operate safely and efficiently. VI. Applications of Load Resistors A. Power Electronics 1. Inverters and ConvertersLoad resistors are essential in testing inverters and converters, allowing engineers to evaluate their performance under various load conditions. 2. Power Supply TestingIn power supply testing, load resistors simulate real-world loads, helping engineers assess the reliability and efficiency of power sources. B. Automotive Applications 1. Load Testing in Electric VehiclesIn electric vehicles, load resistors are used to test battery performance and ensure that the vehicle's electrical systems function correctly. 2. Sensor SimulationLoad resistors can simulate sensor loads, allowing engineers to test and calibrate automotive systems without needing actual sensors. C. Audio Equipment 1. Speaker Load SimulationIn audio applications, load resistors simulate speaker loads, enabling engineers to test amplifiers and other audio equipment without connecting actual speakers. 2. Amplifier TestingLoad resistors are used in amplifier testing to ensure that the amplifier can handle the required load without distortion or failure. D. Industrial Applications 1. Motor TestingLoad resistors are employed in motor testing to simulate the load that a motor would experience in real-world conditions, helping engineers evaluate performance and efficiency. 2. Equipment CalibrationIn industrial settings, load resistors are used for calibrating equipment, ensuring that machines operate within specified parameters. VII. Selecting the Right Load Resistor A. Key Specifications to ConsiderWhen selecting a load resistor, several key specifications must be considered:1. **Resistance Value**: The resistance value should match the requirements of the application.2. **Power Rating**: The power rating indicates how much power the resistor can handle without overheating.3. **Tolerance**: Tolerance specifies the allowable deviation from the stated resistance value. B. Environmental Considerations 1. Temperature CoefficientThe temperature coefficient indicates how the resistance value changes with temperature. Selecting a load resistor with a suitable temperature coefficient is essential for maintaining accuracy in varying conditions. 2. Material and ConstructionThe material and construction of the load resistor can affect its performance and durability. Common materials include carbon, metal film, and wire-wound designs. C. Application-Specific RequirementsDifferent applications may have unique requirements, such as size constraints, mounting options, and specific performance characteristics. It's essential to consider these factors when selecting a load resistor. VIII. Safety Considerations A. Risks Associated with Load ResistorsWhile load resistors are generally safe to use, there are risks associated with overheating and electrical shock. Proper precautions should be taken to mitigate these risks. B. Best Practices for Safe UseTo ensure safe use, follow these best practices:- Always use load resistors within their specified ratings.- Allow adequate ventilation to prevent overheating.- Use appropriate protective equipment when working with electrical components. C. Importance of Proper Ratings and SpecificationsUsing load resistors with the correct ratings and specifications is crucial for safety and performance. Always consult datasheets and manufacturer guidelines when selecting and using load resistors. IX. ConclusionLoad resistors are vital components in the field of electrical engineering, providing essential functionality in testing, simulation, and circuit stability. As technology continues to evolve, the demand for more advanced load resistors will likely increase, leading to innovations in design and application. Understanding the role of load resistors and their various types and applications is crucial for engineers and technicians working in modern electronics. X. References A. Suggested Reading- "The Art of Electronics" by Paul Horowitz and Winfield Hill- "Electrical Engineering 101" by Darren Ashby B. Relevant Standards and Guidelines- IEEE Standards for Electrical Components- IEC Standards for Resistors C. Online Resources for Further Learning- Electronics tutorials on websites like All About Circuits and Electronics Hub- Manufacturer datasheets and application notes for specific load resistorsBy understanding load resistors and their applications, engineers can ensure the reliability and efficiency of their electronic designs, paving the way for advancements in technology and innovation.

阅读更多